TENSIONER

DESCRIPTION

The Tensioner has the main function to apply to the pipes the required tension load, allowing to lay the product Spooled out from fixed or portable carousels, baskets or driven reels (storage device}up to the maximum reachable speed.

Tensioner is installed in middle or tail part of vessel to clamp pipelines with different diameters and then deliver pipes under the sea through conveyor system.

Through the whole pipe welding process, tensioner keeps a constant tension onto pipes. It means that, when the vessel moves, tensioner can deliver pipes to seabed with constant tension to eliminate the influence of vessel moving or sea wave reciprocating.

The control system of this kind of tensioner is auto controlled. We already manufactured 50T & 75T tensioner that attested in projects, and we can also design and manufacture for specific demands.

STRUCTURE

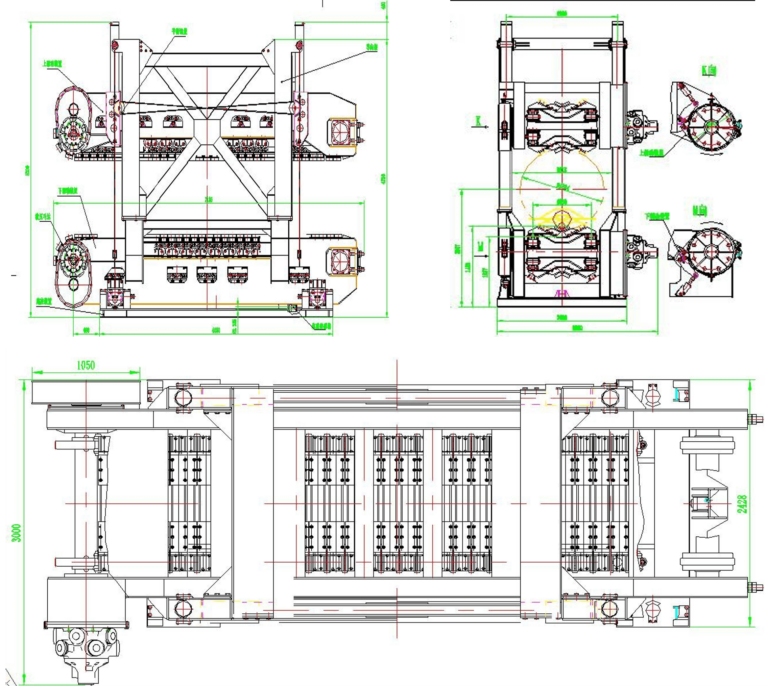

Tensioner is made up by 6 parts: Top actuating device, bottom actuating device, foundation, guide frame, hydraulic control system and electric control system. The equipment is mainly composed by welded steel structures on which other subassemblies are installed. 4 or 2 tracks constrained to the main structure driven by AC electrical motors or hydraulic motors and clamping the pipe and allowing, by friction, to keep the pipe line.

Technical Parameters

| Max Tension (KN) | Max chucking power (KN) | Pipe diameter (mm) | Max Angle of inclination | Max speed (m/min) | Max system pressure (Mpa) | Total power (kw) | Size (mm) | Weight (T) | |

|---|---|---|---|---|---|---|---|---|---|

| 50T | 500 | 550 | 101~1524 | 5° | 27 | 20 | 180 | 6000*2428*5110 | 52 |

| 75T | 750 | 800 | 101~1524 | 5° | 27 | 20 | 520 | 7123*2428*5120 | 78 |

| 100T | 1000 | 1100 | 101~1524 | 5° | 27 | 20 | 560 | 7518*2428*5408 | 103 |

Control System

Sensors on foundation measure the tension on pipes and then deliver a signal to electric control system. Electric control system compares the signal to standard value and feedback a modification signal to hydraulic system. After all the hydraulic system can control the power and direction of hydraulic motor to make sure the tension on pipe constant. Electric control system includes distant control and on-site control. Both the electric and hydraulic control system have security program to accomplish auto break if power failure.