Sea water Desalination Unit 2000 T \Day

Technical Proposal

1.System Introduction

1.Introduction :

The sea water desalination system is designed by international advanced reverse osmosis technology and

optimized system.

According to the water quality report information provided by the customer, the raw water is sea water, and the product water quality is <500ppm.

According to the water source part of the data, the following process design is made.

2.Principles of Compilation

- Strictly implement the national environmental protection policy; in line with relevant national laws & regulations, policies, norms and standards; give full play to the social, environmental and economic benefits of project construction.

- We choose the water treatment process according to local conditions, and we strive to the mature & reliable, efficient & energy saving process to ensure the effect of water treatment and the purpose of using advanced, economically reasonable technology.

- In this proposal, we choose specialized equipment that adopted advanced, reliable, efficient, simple operation & maintenance method, which offer the room for selection and comparison.

- We implement energy conservation policy to reduce the cost of operation and management.

- Modernized & automatic controlling technology is adopted to achieve automatic management, and reduce labor intensity and management costs.

- The proposal reasonably determines the scale of the project to make the limited water resource maximize its benefits.

- The water treatment system is stable and reliable, cause double circuit power supply, enough handling facilities and operation equipment are adopted.

- The proposal actively and securely uses new technology, advanced equipment, material.

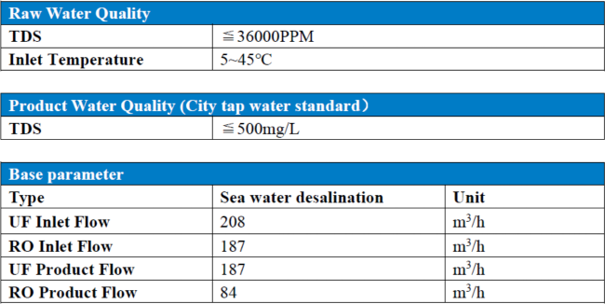

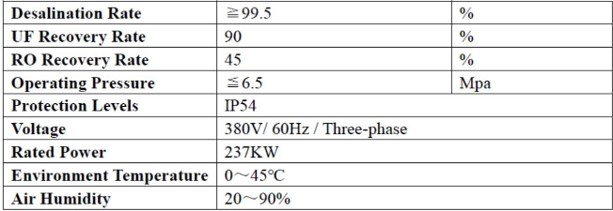

Base Parameters

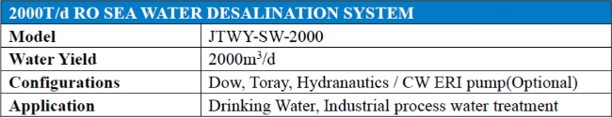

1.4 Product Specification

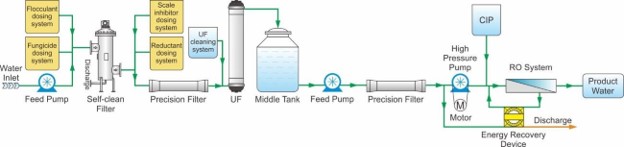

2.4 Process Flow Diagram

3.System Design Specification

1.System design implementation standard

- Classification, technical requirements, test methods, inspection rules, marking, packaging, transportation and storage Execution: CB/T 3753-2019.

- National standard for city tap water: GB5749-2022.

- Ship noise limit and measurement method standard: GJB 763.5-1989.

- Specification for construction and acceptance of low-voltage electrical installations for electrical installations: GB50254-9.

- Low-voltage distribution equipment and line design specifications: GB50054-2011

- Chemical equipment, pipeline anti-corrosion design conditions: HG/T 20679-2014.

- Rubber gasket for pipeline: JB/T87-94.

- Pipe flange standard: JB/T81-94.

- Pipe flange technical conditions: JB/T74-94.

- Lining plastic (PP, PE, PVC) steel pipe and fittings: HG20538-92.

- Rubber-lined steel pipe and fittings: HG21501.

- The manufacturing process and materials of imported equipment shall comply with the

standards or equivalent standards involved in the industrial regulations of the American Society of Mechanical Engineers (ASME) and the American Society for Testing and Materials (ASTM).

3.2 Acceptance standard

National Sanitary Standard for drinking Water “GB5749-2022”.

4.Electrical Control Instructions

1.Electrical Design Basis

Electrical professional design standards: “Industrial and Civil Power Distribution Design Manual.” Low-voltage distribution cabinets, power control box related standards:

GB7251-87 “low-voltage switchgear and control equipment.” JB/T9661 “Low-voltage withdrawable switchgear”.

IEC60439-1 “Low-voltage switchgear and control equipment”.

Control box protection level: GB4942.2-1985 “low-voltage electrical enclosure protection level”. Safety distance between electrical appliances:

GBJ54-83 “Design Specification for Low Voltage Distribution Devices and Circuits”.

2.Electrical System Description

System voltage: 380V / three phase / 60HZ (can be changed according to customer’s needs).

The system air switch, contactor and thermal relay are evenly distributed by Schneider International. The installation of power distribution cabinets, control cabinets, air switches and disconnectors are safe

and reliable. Set the ground wire according to the standard.

5. Product Detailed Image (project case)

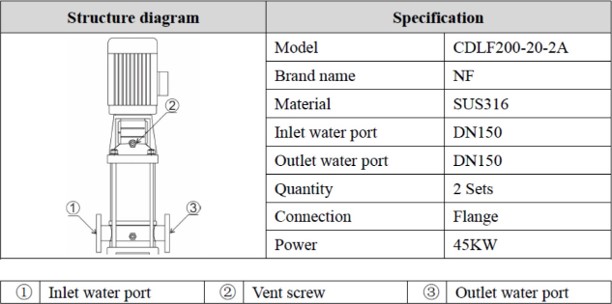

Feed water pump

Parts specifications and names

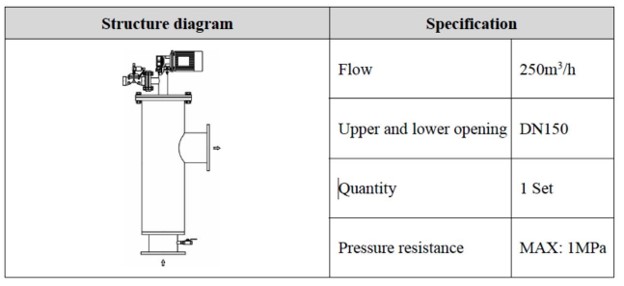

Function Mainly for multi-media filter and precision filter to provide power for fast rinse and back washing. Self-clean filter Parts specifications and names

Function and working principle

The self-cleaning filter system mainly removes large particulate matter such as algae and rust in raw water. It can be extremely effective in repelling colloids, suspended solids, large particle impurities, etc., which are very sensitive to reverse osmosis systems. It has a unique uniform water distribution method, which minimizes the pollution index and turbidity of raw water, and can meet the pollution index requirements of reverse osmosis system for a long time. The self-cleaning filter consists of multiple sets of filter units, which can automatically clean each unit one by one, ensuring stable operation of the system without stopping the machine, thus ensuring the water quality of the membrane system.

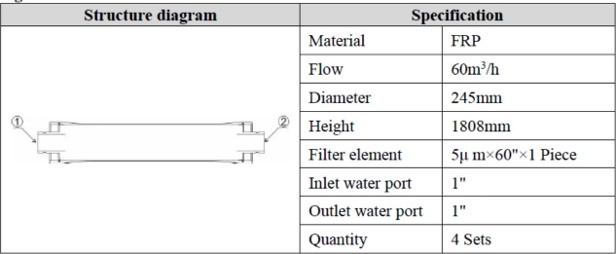

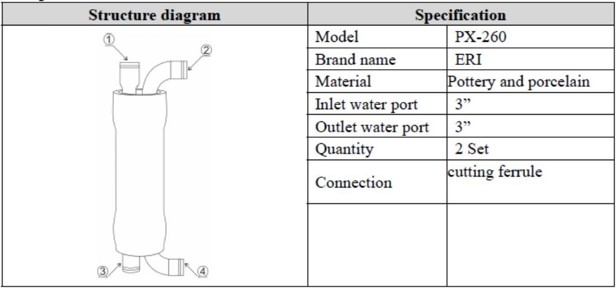

Precision filter

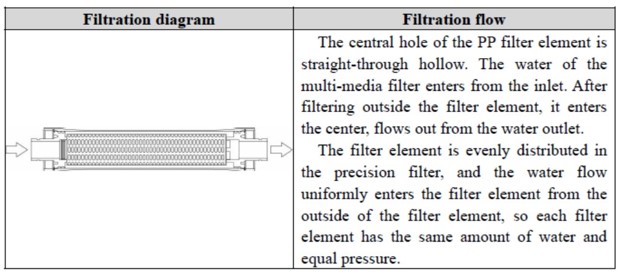

►Diagram of the Precision filter

►Working principle

The precision filter is the last barrier before reverse osmosis. It contains a PP core with a filtration accuracy of 5μm. Its function is to trap particles larger than 5 microns in the influent water to ensure that the reverse osmosis membrane is not scratched by large particles. Because the thickness of the reverse osmosis membrane is about 10 microns, under the speed-up of the high pressure pump, the larger particles in the raw water easily damage the desalted skin layer on the surface of the reverse osmosis membrane may even penetrate the reverse osmosis membrane module. So usually a 5 micron precision filter is installed to ensure the safety of the reverse osmosis membrane.

Since the precision filter is 100% full-filter, the particles intercepted by the filter surface will accumulate over time, so the PP filter needs to be replaced periodically, and the replacement cycle varies depending on the turbidity of the inlet water.

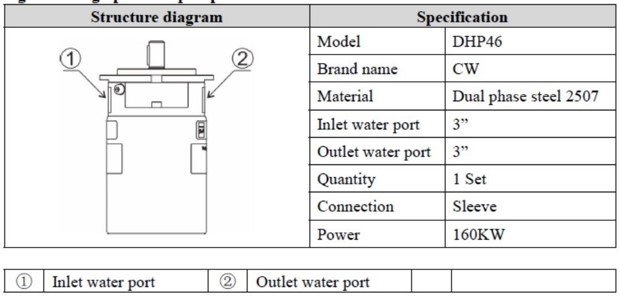

High pressure pump

►Diagram of high pressure pump

►Function

The function of the high pressure pump is to provide sufficient water inlet pressure for the reverse osmosis unit to ensure the normal operation of the reverse osmosis membrane. According to the characteristics of reverse osmosis itself, it is necessary to have a certain driving force to overcome the resistance such as osmotic pressure, and to ensure the designed water production.

High pressure pump

►Parts specifications and names

►Function

The pressure energy of the high-pressure concentrated seawater of the reverse osmosis system is recovered and reused, thereby reducing the water-consuming energy consumption and the water-making cost of the reverse osmosis seawater desalination.

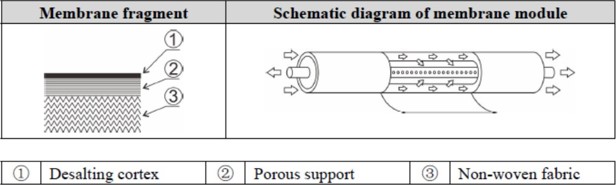

RO system

►Parts specifications and Diagram

The reverse osmosis rated water production of this system is 2000m3/d, and 168 piece 400 membrane components are used. The structure and working principle of each membrane component are the same. The following figure shows a membrane component as an example.

►RO membrane working principle

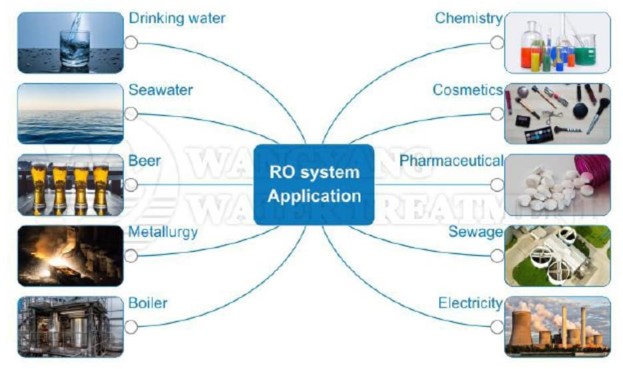

Reverse osmosis technology is a membrane separation filtration technology that uses pressure difference as power. It originated from the research of aerospace science and technology in the 1960s in the United States, and then gradually transformed into civilian use. It has been widely used in scientific research, medicine, food, beverage, desalination. And other fields.

The reverse osmosis device is the most important desalination device in the system. The reverse osmosis

system utilizes the characteristics of the reverse osmosis membrane to remove most of the soluble salts, colloids, organic matter and microorganisms in the water. After pretreatment, the qualified pretreated effluent enters the membrane module, and the water molecules pass through the membrane layer, and after being collected through the collection pipeline, they are led to the production water pipe and then injected into the intermediate water tank. Conversely, if it cannot pass, it will be concentrated through another collection pipeline and then led to the concentrated water discharge pipe and discharged outside the system. The system’s water inlet, water production and concentrated water pipelines are equipped with a series of control valves, monitoring instruments and program-controlled monitoring operating systems, which will ensure the long-term quality and quantity of equipment can be systematically operated.

The membrane fragment surface shows the structure of the RO membrane. The RO membrane is composed of multiple layers of material, and the most critical part of the filtration of water is the uppermost desalted cortex with a pore size as small as nanometer. Under a certain pressure, water molecules can pass,

but impurities such as inorganic salts, heavy metal ions, organic substances, colloids, bacteria, viruses, etc. in the source water cannot pass through the RO membrane, thereby separate allowing permeable pure water and impervious concentrated water.

Rolling up an RO membrane on a center tube filled with small holes, which is rolled membrane

element installed in the membrane. RO membranes are vacuum-packed at the factory to prevent the loss of microorganisms and moisture, so do not disassemble the membrane components when they are not in use.

Reverse osmosis works differently than a precision filter. The water flow is perpendicular to the filter element in the precision filter. The filter element traps the impurities on the surface of the filter element and the water passes through the filter element. Reverse osmosis is a cross-flow filtration.

The water flow is parallel to the surface of the membrane. Under high pressure, water molecules pass through the membrane and enter the central tube, while the salt is intercepted on the membrane surface and carried away with the water flow.

The RO membrane uses cross-flow filtration because the PP filter is a disposable consumable, which is replaced when plugging. However, the RO membrane determines its inability to filter in its entirety from its initial design and operation. When the material of impurities and salts in the water, it will soon accumulate on the surface of the membrane and the membrane will soon produce no water.

As one of the core parts of the whole system, reverse osmosis has a great impact on the quality of the product water.

► Choose Our Technology

- With strict quality management, our factory has obtained ISO 9001-2015 Quality Management Systems Certification Certificate, ISO 14001-2015 Environmental Management System Certification Certificate, ISO 45001-2018 Occupational Health And Safety Management System Certification Certificate, ship inspection and fish type approval certificate, 4 high-tech product certificate, 15 water treatment patents and

- software copyrights.

- We have a professional technical team to provide strong technical service support.

- Provide complete water treatment solutions according to customer needs.

- On-time delivery to ensure excellent quality.

- 13 years of industry R&D experience, supporting OEM & ODM.

►Reverse Osmosis Technology

The reverse osmosis membrane is an artificial semipermeable membrane made of a semi-permeable membrane that has certain characteristics and is a core component of reverse osmosis technology.

The principle of reverse osmosis technology is to remove these substances and moisture according to the osmotic pressure of the solution, according to the fact that other substances cannot pass through the semipermeable membrane. The membrane pore size of the reverse osmosis membrane is very small, so that

dissolved salts, colloids, microorganisms, organic matter, and the like in the water can be effectively removed.

The system has the advantages of good water quality, low energy consumption, no pollution, simple process and easy operation.

Reserve osmosis/RO water treatment equipment is mainly used in electronic industry, semiconductor industry water treatment, chemical industry, pharmaceutical industry pure water treatment and so on. RO system is widely used in school, hotel, hospital, laboratory and many other public area.

- Maintenance Space And Pipe Design